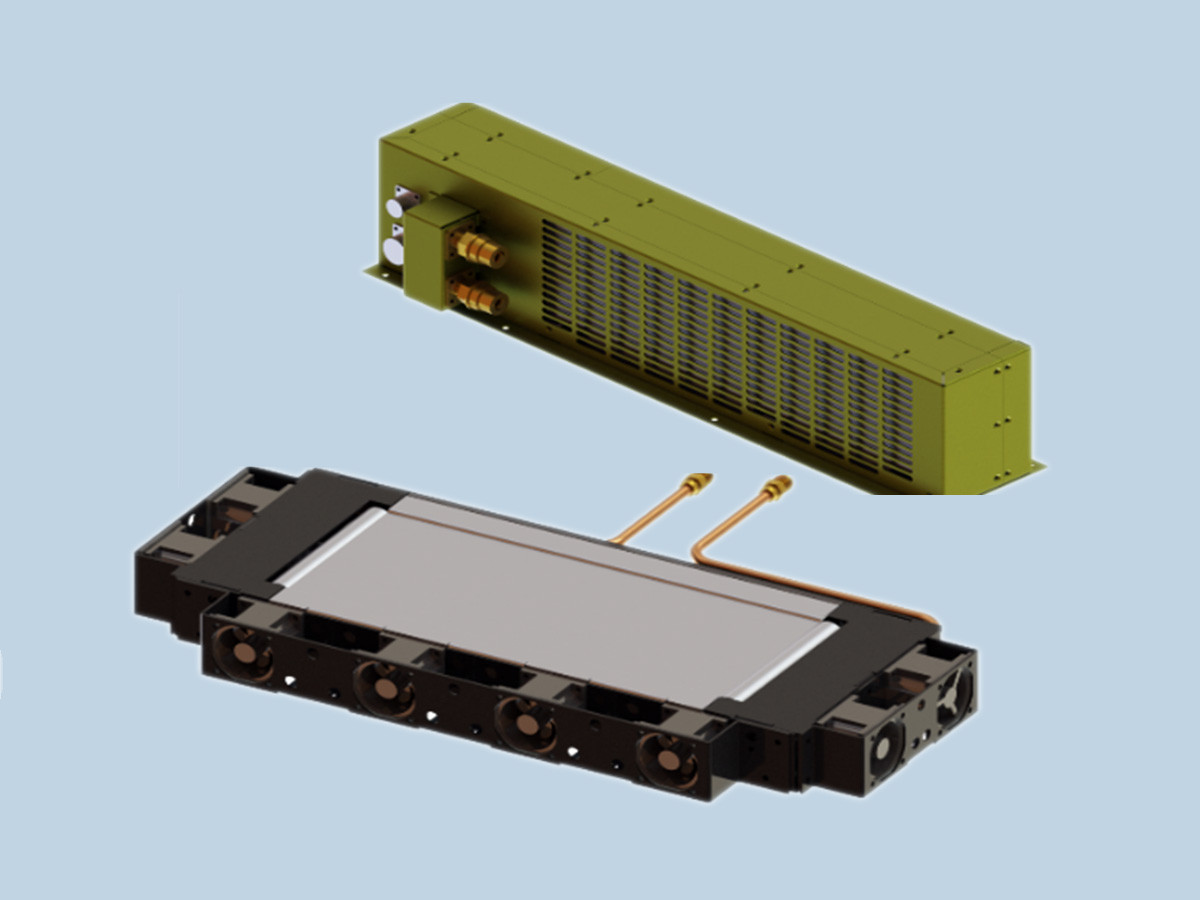

Heat dissipation system for confined space|separated cooling system

- podíl

Heat dissipation for confined space

separated cooling system

This product is a refrigeration system with a refrigerating capacity of 400W, it is designed with split thin section (inner machine height less than 40mm), so as to occupy the precious space as much as possible in the equipment. Inner and outer machine connector both use full sealed quick joint. The inner machine has no water design, and it can carry out self-control without condensate water.

1. Product features

| ①Small size and light weight: The thickness of the inner machine is only 40mm, and the outer machine adopts a slender structure to facilitate the installation and layout in the narrow space. | ②High refrigerating capacity: When the ambient temperature is 40 degrees centigrade and the temperature is 25 degrees in the equipment space, the refrigerating capacity is 400W. (The higher the ambient temperature is, the lower the refrigerating capacity is, and the lower the room temperature is, the lower the refrigerating capacity is). |

| ③High efficiency: The refrigeration efficiency of the small micro refrigeration system is about 2, which is 5 times of the semiconductor refrigeration efficiency, and is far higher than other refrigeration and cooling methods. | ④Easy operation: The refrigerant connection and electrical connection of the product are both plugged by the quick connector. |

| ⑤High temperature control accuracy: The temperature can be manually set on the touch screen, and the product can achieve the temperature control accuracy of 1 degrees centigrade. | ⑥High reliability and safety: product development through a series of reliability and safety testing. The factory production of each product must go through the corresponding type test (vibration, pressure, high and low temperature environment, weather resistance, oil return, condensation, protection, liquid pump / fan components such as reliability, performance, electrical safety etc.). |

⑦Good environmental adoptability: |

2.Product structure and parameters

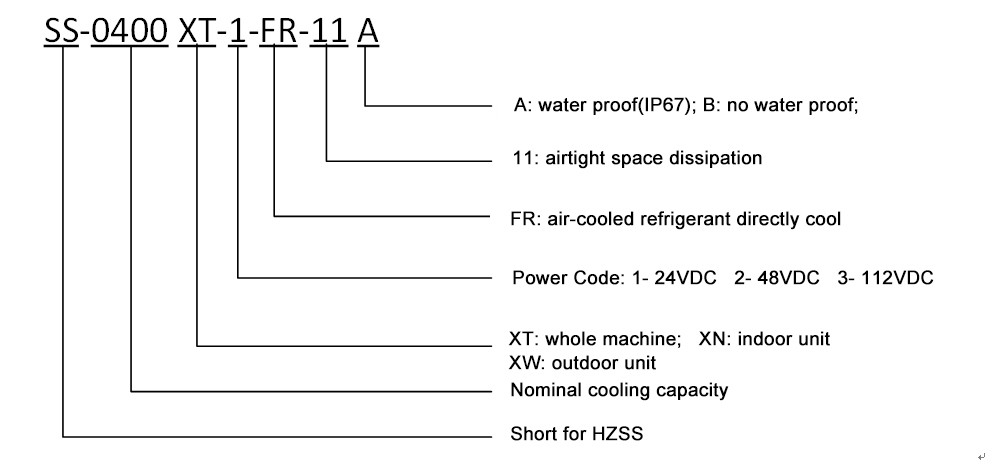

2.1 Naming rules

2.2 Product configuration

| NO. | Component Type | Component Name | Component Description |

|---|---|---|---|

| 1 | Outdoor | Compressor | Miniature DC variable frequency compressor |

| 2 | Condenser | Parallel flow micro-channel heat exchanger | |

| 3 | Cryogen | R134a Cryogen | |

| 4 | Display Panel | Touch panel | |

| 5 | Indoor | Evaporator | Micro-channel heat exchanger |

| 6 | Housing | Shell | Aluminum alloy shell,Surface anodic oxidation treatment |

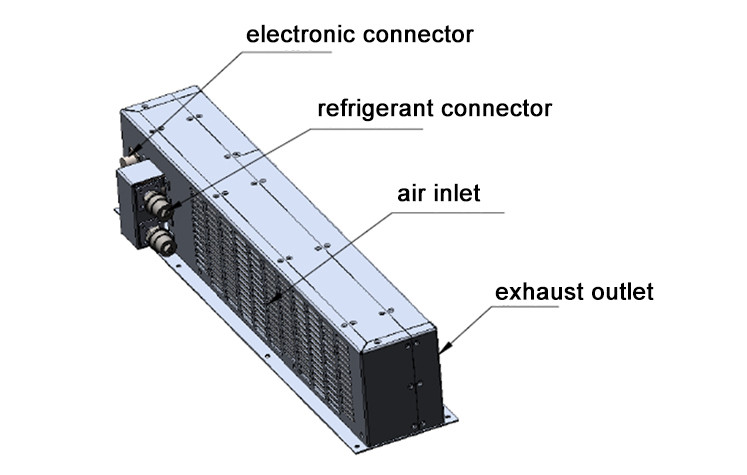

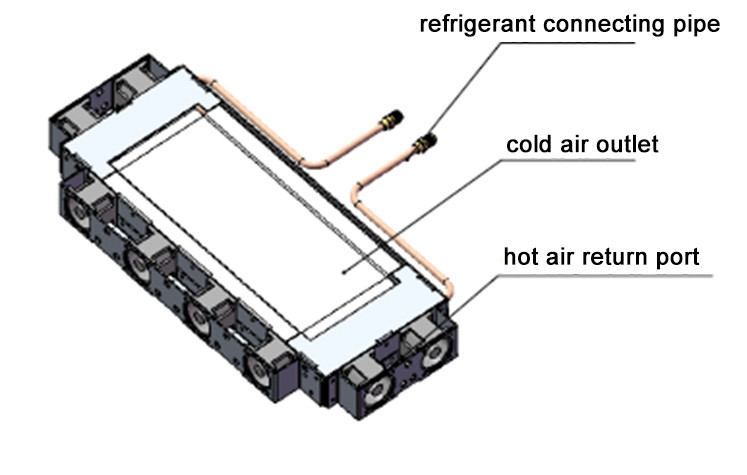

2.3 Host structure

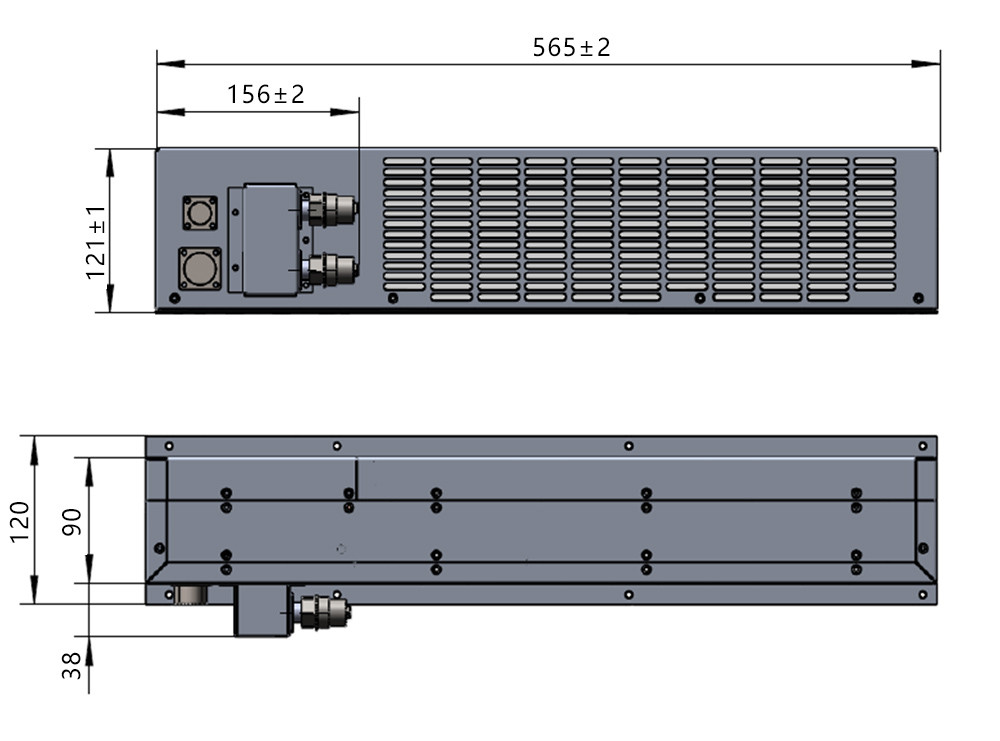

2.4 Host dimension

2.5 Technical specification table

| Project | Unit | Value | |

|---|---|---|---|

| Nominal refrigerating capacity | W | 400 | |

| Nominal power | W | 155 | |

| Host input voltage | V | DC20~26 | |

| Host rated voltage | V | DC24 | |

| Host Rater current | A | 6.5 | |

| Host maximum current | A | 10.0 | |

| Equipment space temperature range | °C | Suggest:15.0~40.0 | |

| Exterior | Indoor | mm | Long:414 |

| Wide:171 | |||

| High:42 | |||

| Outdoor | mm | Long:565 | |

| Wide:90 | |||

| High:121 | |||

| Temperature control mode | Touch screen settings, host self-control | ||

| Working environment temperature | °C | -40~+55 | |

| Storage environment temperature | °C | -40~+70 | |

| Host Net weight | Indoor | kg | 2.0 |

| Outdoor | kg | 4.2 | |

| Host noise | dB(A) | 57(indoor)/ 52(outdoor) | |

| Circulating medium | 100%pure water or distilled water | ||

| Appearance material | ■Aluminum/ ■Silvery □Blue □Black □Others | ||

| Note: Nominal working condition: The ambient temperature is 40 degrees centigrade. The Internal air temperature is 25 degrees centigrade. | |||

3.Product performance

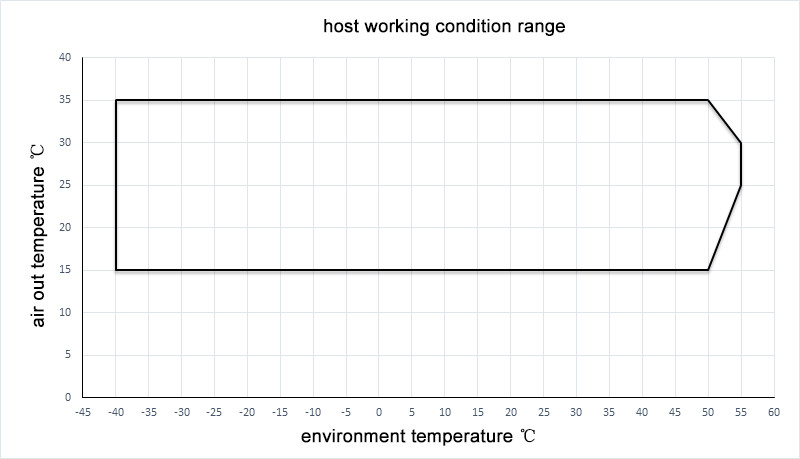

3.1Working range

Note: It will warm when the machine working a long time over lord.

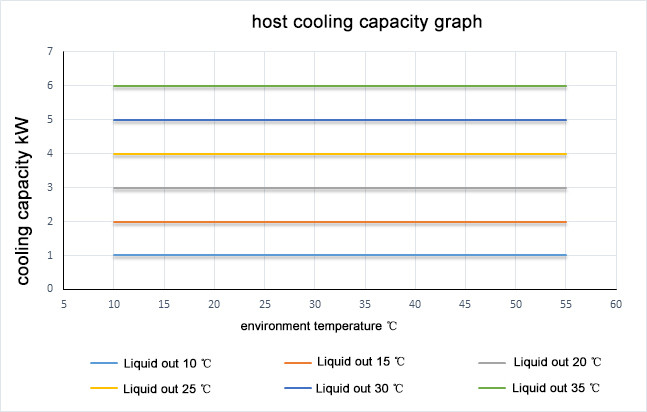

3.2 Refrigerating capacity

4.Fault code

| Code | Fault | Code | Fault |

|---|---|---|---|

| F1 | Compressor overload/condenser fouling | F16 | Fan 3 overload |

| F2 | Compressor self-protection | F17 | Fan 4 broken line |

| F3 | Compressor communication failure | F18 | Fan 4 overload |

| F4 | High temperature protection of compressor | F26 | Environmental temperature sensor fault |

| F11 | Fan 1 broken line | F27 | Liquid temperature sensor fault |

| F12 | Fan 2 broken line | F28 | Fault of inlet temperature sensor |

| F13 | Fan 3 broken line | F42 | Environmental temperature anomaly |

| F14 | Fan 1 overload | F43 | Anti-freezing protection |

| F15 | Fan 2 overland | F44 | Overvoltage/under voltage of power supply |

Note:When some fault occurs, the host will continue to operate, but it will automatically take some recovery measures or alternative measures. | |||